Nanostructured Zinc-Nickel vs Conventional: 9x More Protection with Sapucaia's NanoGalv®

- Equipe - Sapucaia

- 5 de out. de 2025

- 2 min de leitura

Conventional Zinc-Nickel vs. Nanostructured Zinc-Nickel: What's the Difference?

In the automotive, solar energy, and oil & gas industries, zinc-nickel (Zn-Ni) coatings are widely used to extend the life of corrosion-prone parts and fasteners. However, there's a key difference that often goes unnoticed: traditional Zn-Ni is not the same as nanostructured Zn-Ni .

While the conventional process offers good protection, nanotechnology has brought a leap in performance with NanoGalv® , a coating developed by Modumetal and available in Brazil with application by Sapucaia .

What is Conventional Zinc-Nickel?

Traditional Zn-Ni is a homogeneous coating applied by electroplating. It meets automotive and industrial standards and offers corrosion resistance ranging from 500 to 1,500 hours in salt spray (depending on thickness and finish).

🔹 Main features:

Homogeneous Zn-Ni alloy with 12–16% nickel;

Need for thick layers (8–15 μm typical);

Good protection, but limited in extreme environments;

Uneven thickness in threads, corners and cavities;

Greater consumption of energy, metals and waste generation.

What is Nanostructured Zinc-Nickel (NanoGalv®)?

NanoGalv® is a Zn-Ni coating obtained through a patented nanostructured electrodeposition process.

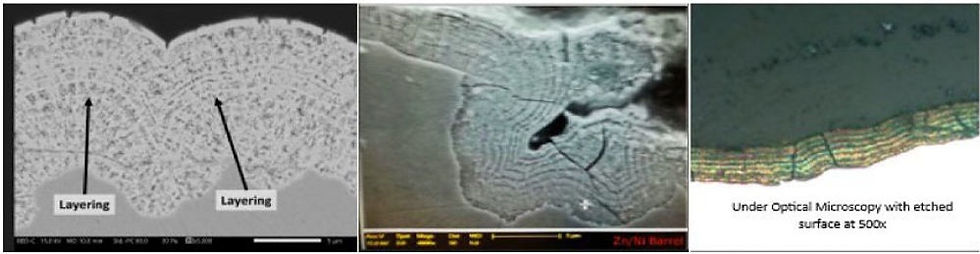

Unlike conventional coatings, it does not form a homogeneous layer, but rather several overlapping nanometric layers that act as a multiple barrier against corrosion.

🔹 Main features of NanoGalv®:

Corrosion resistance up to 9x greater per unit thickness ;

Exceeds 3,000 hours in ASTM B117 salt spray with only 3–5 μm;

Low Hydrogen Embrittlement (LHE) process – reduces the risk of hydrogen embrittlement;

Better uniformity in critical areas such as threads and edges;

Up to 68% less waste and lower energy consumption ;

Direct replacement for conventional cadmium, zinc nickel and PTFE in critical oil & gas applications.

Direct Comparison

Feature | Conventional Zn-Ni | Nanostructured Zn-Ni (NanoGalv®) |

Structure | Homogeneous alloy | Overlapping nanometric layers |

Typical thickness | 8–15 μm | 3–5 μm |

Corrosion resistance (ASTM B117) | 500–1500 h | > 3,000 h |

Uniformity in geometries | Low | High |

Hydrogen embrittlement | Present risk | LHE Process (low risk) |

Sustainability | High consumption and waste | Up to 68% less waste and metals |

Why does this matter?

The choice between conventional Zn-Ni and nanostructured Zn-Ni can mean:

Longer component life;

Reduction of maintenance costs;

Lower environmental impact;

Better performance in critical sectors such as automotive, solar and oil & gas.

👉 Sapucaia is an authorized supplier of NanoGalv® in Brazil, bringing the most advanced corrosion protection technology to the national market.

🔗 Contact our team and find out how to apply nanostructured zinc-nickel to your projects.